Evaluating Dispersing Agents for Yellow Oxide in Acrylic SB Systems

What are dispersing agents used for?

Available for both waterborne (WB) and solvent-borne (SB) coatings and inks, dispersing agents wet pigments, speed up dispersion, and stabilize coatings and inks. Using dispersing agents will result in better color development, opacity, viscosity reduction, and prevent pigment floating and flooding. Please visit our Dispersing Additives page for our full lineup of JebChem dispersing agents.

How did we evaluate our dispersing agents?

The dispersing agents were tested by highly skilled lab technicians at Jebsen & Jessen Ingredients’ Coating Innovation Center using the following equipment, raw materials and paint preparation methods. To test the performance, properties such as particle size (fineness), viscosity, and color performance were evaluated against an industry benchmark dispersing agent.

Equipment

1. High-speed shaker (Model SK550)

2. Bar coater (no.200)

3. Black/white hiding paper

Raw Materials

1. Acrylic resin

2. Solvent: toluene, xylene

3. Dispersing agents: Benchmark, JebChem 8531,

Jebchem 8163

Paint Preparation

The pigment paste for SB system was prepared as follows:

Step 1. Thoroughly mix together Acrylic Resin (53.19%), Xylene (2.13%) and Toluene (2.13%) at normal mixing speed

Step 2. Add Dispersing Agent (10.64%) to the mixture and keep stirring until homogeneous

Step 3. Add Yellow Oxide Pigment (31.91%) to mixture and keep grinding paste for 1.5 hours to achieve desired fineness

4. After achieving fineness as per specification, D/D pigment paste for full shade. For reduced shade tint, mix 2% pigment paste into S/B commercial acrylic white base

Performance test results

The pigment pastes produced by Jebsen & Jebsen’s Coating Innovation Center performed well, indicated by basic paint properties such as viscosity and fineness. More specifically, the lab results indicate that the viscosity of the pastes produced with JebChem 8531 and JebChem 8163 have good stability and the viscosities are lower than that of the benchmark dispersing agent.

Viscosity (KU) / Fineness (microns)

| Initial | Stability 50°C @ 7 days | |

|---|---|---|

| Benchmark | 93 / <10 | 95 / <10 |

| JC 8531 | 84 / <10 | 87 / <10 |

| JC 8163 | 84.5 / <10 | 89.5 / <10 |

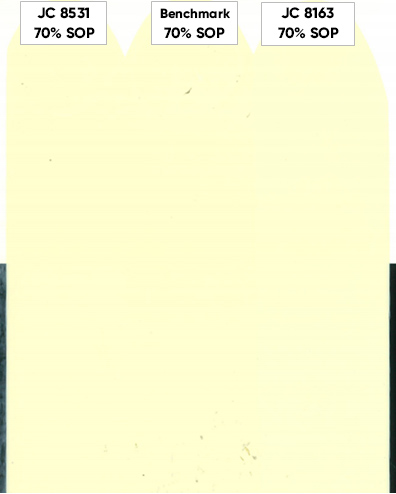

The full shade test

The full shade sample test is used for determining color strength. A carbon black paste is drawn down 200 microns to compare with standard. The test result shows that yellow oxide pigment paste produced with JebChem 8531 and JebChem 8163 provides good compatibility and color strength comparable to industry benchmark.

The reduced shade test

The reduced shade test is used for evaluating paste performance in its ability to provide color intensity when tinting a white base. As before, the test result shows that yellow oxide pigment paste produced with JebChem 8531 and JebChem 8163 provides good compatibility and color intensity comparable to industry benchmark.

Tinting performance using spectrophotometer

The pigment pastes produced with JebChem 8531 and JebChem 8163 had strong performances for all significant color properties, such as color data and gloss color strength from full shade and reduced shade paint film. To obtain a copy of our technical report containing complete spectrophotometer results and analysis, please contact our JebChem team.

Conclusion

The pigment pastes produced with JebChem Dispersing Agents performed well compared to the benchmark when evaluating factors such as particle size (fineness), viscosity, color performance, and full shade and reduced shade color strength.

Particle size (fineness)

The primary criterion for determining quality of dispersion is particle size (after grinding), whereby a smaller particle size indicates higher quality dispersion. Using a gradiometer, test results indicate that the fineness of the pastes produced with JebChem 8531 and JebChem8163 after grinding, is lower than 10 microns, same as the benchmark.

Viscosity

The viscosity of the yellow oxide pigment is also important. According to the test results, the viscosity of JebChem 8531 and JebChem 8163 after grinding was lower than the benchmark with good stability.

Color Performance

Many indicators were evaluated for pigment paste efficiency in acrylic base i.e, Color strength, Color intensity.

Full Shade (color strength)

showed desirable results with sample color strengths of JebChem 8531 and JebChem8163 comparable to benchmark

Reduce Shade (color intensity)

showed that the tinted paste sample with JebChem 8531 was comparable to the benchmark

Don’t just take our word for it.

We have free samples available for your team. Click below to find out more about the products used in this project.

Related Articles

JebChem 1900 – Silicon Antifoam Agent

JebChem 1900 is a highly efficient silicon anti-foam agent for solvent-based systems, specialised for high-build epoxy, PU, UV, and pigmented coatings.

JebChem 3378 – Polyether Modified Polysiloxane

JebChem 3378 is a polyether modified polysiloxane substrate-wetter with excellent slip properties, suitable for most solvent-based, water-based coatings and solvent-free systems.

JebChem 7602 – Silica Matting Agent

JebChem 7602 is a silica matting agent for water-based overprint varnish (OPV). This product is used in paint and printing inks to create a non-glossy surface with a smooth touch and high transparency.